Exhaust Fans

Exhaust Fans

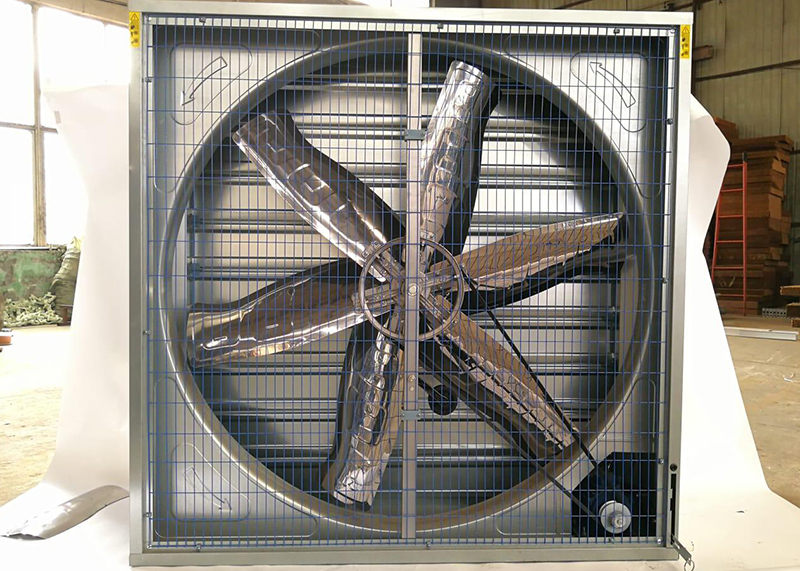

Product Description

- The industrial exhaust fans from Revlon Industries are essential devices designed to enhance air circulation and ventilation in commercial and industrial environments. Engineered for robust performance, these fans efficiently remove stale air, harmful fumes, and excess humidity, ensuring a safer and more productive workplace. Built to withstand demanding conditions, they are vital for maintaining optimal air quality in factories, warehouses, and workshops.

Application

- According to the factory's industry features, Revlon industrial exhaust fans are the perfect solution for enhancing ventilation and air quality in various industrial environments. Our exhaust fans are designed with low power consumption to address issues such as poor air quality and uncomfortable working conditions, ultimately helping to improve employee satisfaction and retention.

- Depending on the specific air change requirements, noise restrictions, investment budget, and operational needs, we offer a range of Revlon exhaust fans tailored for different applications. Options include single-speed, two-speed, or variable-speed models, as well as three-phase or single-phase configurations.

Design and Benefits

- Sleek and compact design that fits seamlessly into various interiors without taking up too much space.

- High-quality aerodynamic blades enhance airflow while minimizing noise for quiet operation.

- Made from corrosion-resistant materials for durability, suitable for high-moisture areas.

- Energy-efficient with low power consumption, leading to cost savings and environmental sustainability.

- Easy installation with a quick and straightforward setup process for hassle-free use.

- User-friendly maintenance designed for easy cleaning and upkeep, ensuring long-term performance.

Technical Parameter

| Model | Diameter | Blades Rotational Speed | Motor Rotational Speed | Air Flow (m3/h) | Total Pressure | Noise Decibels | Power | Rated Voltage | Thickness |

|---|---|---|---|---|---|---|---|---|---|

| WB-600 | 580 | 1400 | ≥1400 | 9500 | 55 | ≤70 | 370 | 380 | 400 |

| WB-800 | 710 | 660 | ≥1400 | 22000 | 60 | ≤70 | 370 | 380 | 400 |

| WB-900 | 750 | 630 | ≥1400 | 25000 | 65 | ≤70 | 550 | 380 | 400 |

| WB-1000 | 900 | 610 | ≥1400 | 30000 | 70 | ≤70 | 550 | 380 | 400 |

| WB-1100 | 1000 | 600 | ≥1400 | 35000 | 70 | ≤70 | 750 | 380 | 400 |

| WB-1220 | 1100 | 460 | ≥1400 | 38000 | 73 | ≤70 | 1100 | 380 | 400 |

| WB-1380 | 1250 | 439 | ≥1400 | 44000 | 56 | ≤70 | 1100 | 380 | 400 |